Our main displayable procedures are: extrusion, calendering, vacuum forming and foaming, spraying, cold/hot pressing, punching, water jet cutting and HF welding. Additionally, we offer meltblown technology in order to produce microfiber absorber-fleece under the brand name Sonozorb B.

Due to our in-house laboratory facilities we are able to develop tailor-made polyurethane foam applications and improve them constantly. We specialize in the development of foams (PUR), nonwovens (BW, PP, PET, basalt, glass wool), plastics (PP, EPDM) as well as aluminum and combinations thereof.

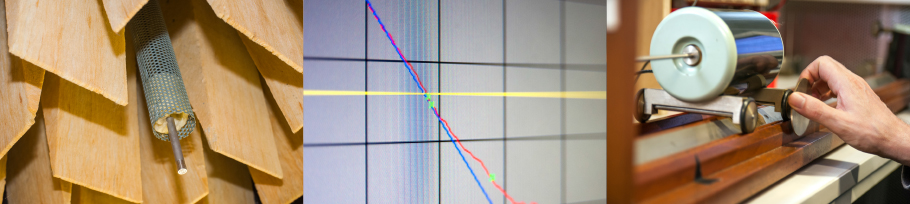

Our acoustic specialists have all the relevant measuring devices for components and semi-finished products.

Our in-house CAD workstations, offline robot programs and various simulation tools complete the efficiency of our R&D department.

Of course, comparative analyzes and interpretations are being carried out here as well.

Our technical center - equipped for every challenge

We use our pilot plants for both, experimental determination of production parameters as well as production of series and spare parts. Bringing together cutting edge technology with an experienced technical team, we can meet specific, complex and demanding customer tasks. Simply speak with our experts at the development department.

Our material laboratory – cutting-edge technology for tailored acoustic solutions

Our material laboratory is based on excellent technical equipment. Experienced chemists and technical assistants ensure that specific customer needs are taken into account optimally when developing raw material formulations. Of course, we carry out these measurements as a service for you. Simply contact our experts at the development department.

Our acoustic laboratory - because optimum function is not a matter of luck.

Our acoustics laboratory has all the essential instruments for characterizing materials, two-dimensional semi-finished products, finished components and their combinations. Therefore, the measuring of extremely small sample surveys as well as complete vehicle parts (in cabin Alpha for in-house development and service) can be offered.

In addition to measuring analyzes and interpretation by comparing with the relevant theory is always possible. Give us a call, your request will be dealt with as quickly as possible.